News aus der Stahlwelt: Entwicklungen und Innovationen bei UnionStahl

Specially targeted material ensures trouble-free production

UnionStahl supports customers with the complete process takeover and supplies solutions from flame-cut blanks to assemblies.

UnionStahl supplies chain links and wear plates for hydraulic steel construction

UnionStahl supplies wear plates for chain links reliably and flexibly for hydraulic steel construction. Suitable plates now available immediately.

Gusset plate made from LR-EH36 Z35 for shipbuilding

Precisely milled from 350 mm thick LR-EH36 with Z35: gusset plate for the highest demands in shipbuilding – including tested material properties.

Tailor-made wear parts made from 450HB – efficient, durable, precise

Autogenous blanks made of 450HB wear-resistant steel – precise, durable, immediately available. UnionStahl offers strong solutions for recycling & industry.

UnionStahl: Customized flame-cut blanks in extra width

Precise flame-cut parts up to 4,000 mm wide: UnionStahl offers high-quality oxyfuel, plasma and laser cutting. Efficient planning & fast delivery. Find out more now!

UnionStahl: Increased efficiency through work process optimization

Efficient steel processing with the latest plasma system: UnionStahl optimizes work processes and supplies ready-to-install components from a single source. Learn more!

Rack and pinion production for general overhaul of a jack-up rig: High-strength solutions for maritime challenges

Find out how UnionStahl manufactured racks from high-strength S690QL1 steel with Z35 testing for the general overhaul of a jack-up rig. Precision, resilience and quality management for maritime requirements.

Creusabro® 4800: Wear-resistant pipes for tunnel driving

The initial situation for CREUSABRO 4800: Large dimensions and long service life. UnionStahl has maintained a close business relationship with one of the world’s leading tunnel construction companies for over 15 years.

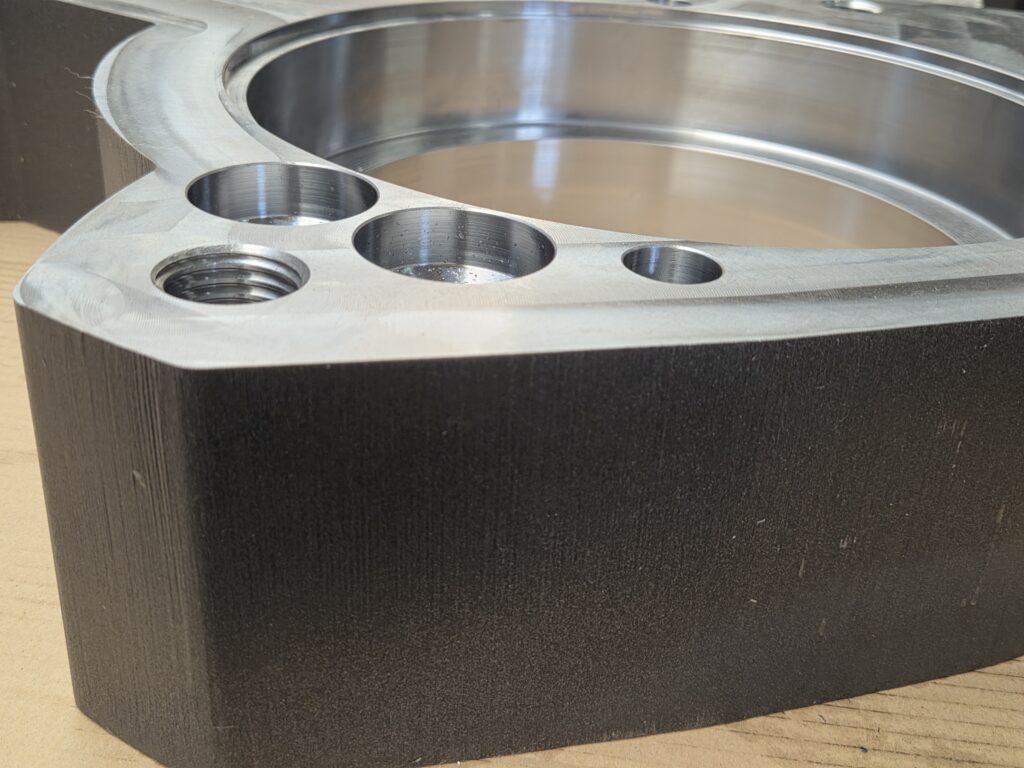

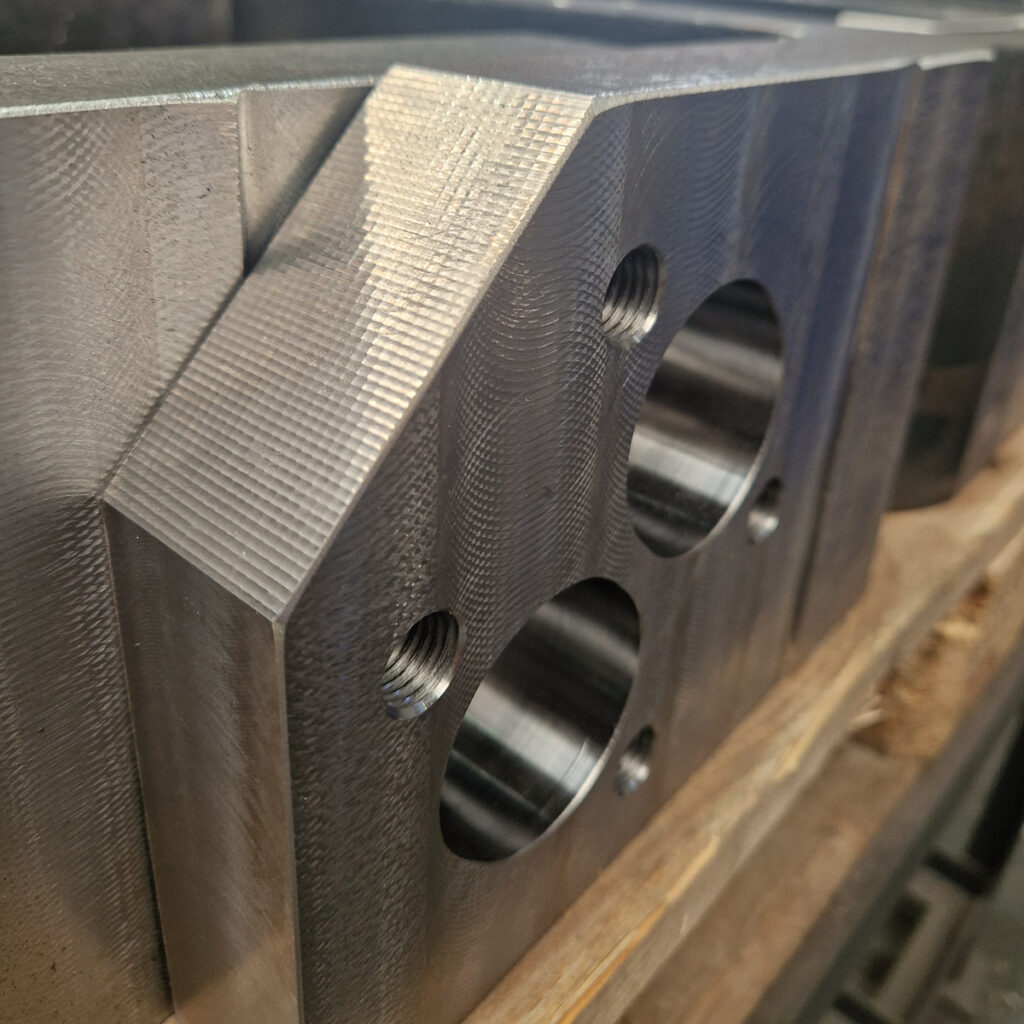

Strong material plus strong processing: the optimum solution for series production

Due to its strength in the area of pre-processing, UnionStahl is often asked to provide support in the development of solutions for subsequent series production. In the current example, UnionStahl has been working for the market leader in the construction of cold milling machines for around twelve years. Initially, UnionStahl supplied flame-cut parts, but later also manufactured machined components in addition to laser parts …