Precision is in our blood.

We make it possible.

Our comprehensive service for you

Your order in the best hands.

To make your order processing as smooth as possible, we offer you a wide range of services that save time, transportation costs and human resources. Benefit from our comprehensive range of services to get your business moving.

Our services include:

- Commenting on specifications and delivery instructions

- Project management

- Storage of customer-specific Steel grades: Hot rolled Sheets, flame-cut part and machined part

- Rays

- Priming

- Staining and oiling

- Markings with tube lettering or stencil

- Packaging according to customer requirements, e.g. pallets treated in accordance with IPPC standard, shrink wrap

- Transport handling and shipping, including container stowage in the port

- Creation of documentation according to customer requirements

Further services: Comprehensive quality assurance processes

- Ultrasonic testing according to European standards, ATSM/ASME 435 and 578 as well as customer specifications

- Dimensional and tolerance checks

- with conventional measuring equipment: Calipers, inside micrometers, limit plug gauges, depth gauges

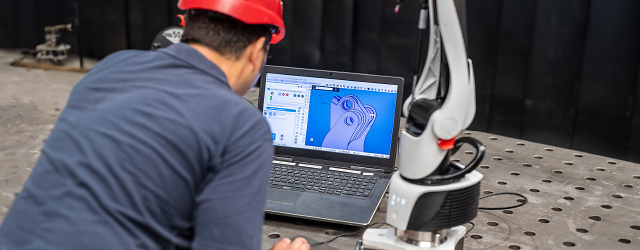

- with tactile measuring arm: direct contact measurement using a contact-active probe on a measuring arm (3 m range), high absolute accuracy, less suitable for area measurements

- with optical detection: contactless measurement by means of absorption and reflection, mounted on a measuring arm (4.5 m range), detects entire surfaces, precise measurement of distance, shape, size and surface roughness, 3D data model creation possible

- First article inspections according to VDA

- Restamping authorization for DNV, LR EMEA, BV

- Special approvals by TÜV, DNV, LR, ABS, BV, etc.

- Mechanical-technological testing by partner laboratories with daily collection of sample coupons, in detail:

- Detection of chemical properties (spectral analysis, PMI)

- Verification of mechanical properties (e.g. tensile test, notched bar impact test, hardness verification, weld-on bending test, tensile test in thickness direction, bending test)

- We also test mechanical properties after simulating annealing (PWHT)

- Purity determination (macrosections and microsections), grain size determination

- Dye penetrant and magnetic particle testing

Additional Steel grades tests are carried out by our appropriately qualified specialists or independent testing laboratories.

We give you our UnionStahl service promise

At UnionStahl, our focus is on first-class service, from the initial inquiry for Hot rolled Sheets, flame-cut parts or ready-to-install components through to delivery. Our highly qualified and dedicated team carefully checks the technical feasibility of your request as soon as we receive it. Our aim is to develop the optimum solution for your application and we will be happy to advise you on quality, tolerances, design and dimensions.

To ensure that we can offer optimum results with maximum cost-effectiveness, our team of specialists checks your inquiry for commercial, industrial and technical optimization options. This enables us to find the right Steel grades and the most efficient manufacturing process for your needs. We carefully process and comment on the specifications or delivery requirements you provide.

We can also carry out additional tests such as ultrasonic tests or measurements of Steel grades tolerances as well as surface treatment and verification of chemical and mechanical properties. If required as an additional service, we can organize third-party acceptance tests by the acceptance company of your choice. Please note that we are the only stockist worldwide authorized to restamp BV and LR EMEA.

As your project progresses, we monitor compliance with delivery times and organize transport by truck, railway, ship or plane. The use of barcode technology enables seamless tracking of your order and facilitates the comparison of order status, Steel grades properties and your customer specifications. This offers you transparency, flexibility and security at every stage of the order process.

The complete and prompt provision of order documentation is a matter of course for us. If required, we also offer the creation of initial sample test reports for components or welded assemblies using a tactile 3D measuring arm if conventional measuring methods are no longer sufficient.