Current information July 2024

July 2024 is full of exciting developments! We summarize the most important events in our article.

Startseite » News » Ready-to-install components for agricultural machinery – from sheet metal to milled parts

In modern agricultural technology, every minute counts – machines have to be robust, low-maintenance and efficient. This is precisely where UnionStahl comes in: With an end-to-end production process from warehousing to cutting and mechanical processing, we supply ready-to-install steel components that go straight to final assembly.

A current project from the agricultural machinery sector shows how this claim is put into practice – with thick-walled S355J2+N, oxy-fuel fired and precision milled – all from a single source.

A long-standing customer from the agricultural machinery industry required steel parts that are used in load-bearing or moving components. The decisive factors were:

The choice was clear: S355J2+N in 160 mm thickness, stored, cut and machined directly at UnionStahl.

The basis of the success lies in the material: UnionStahl keeps S355J2+N in thicknesses of up to 160 mm permanently in stock – thus eliminating the usual procurement time. For the customer, this means less coordination, fewer suppliers and faster processes.

The cutting was carried out using the autogenous burning process. This process is particularly economical and precise for large material thicknesses and simple contours. The quality of the cut edge minimizes reworking and saves time during processing.

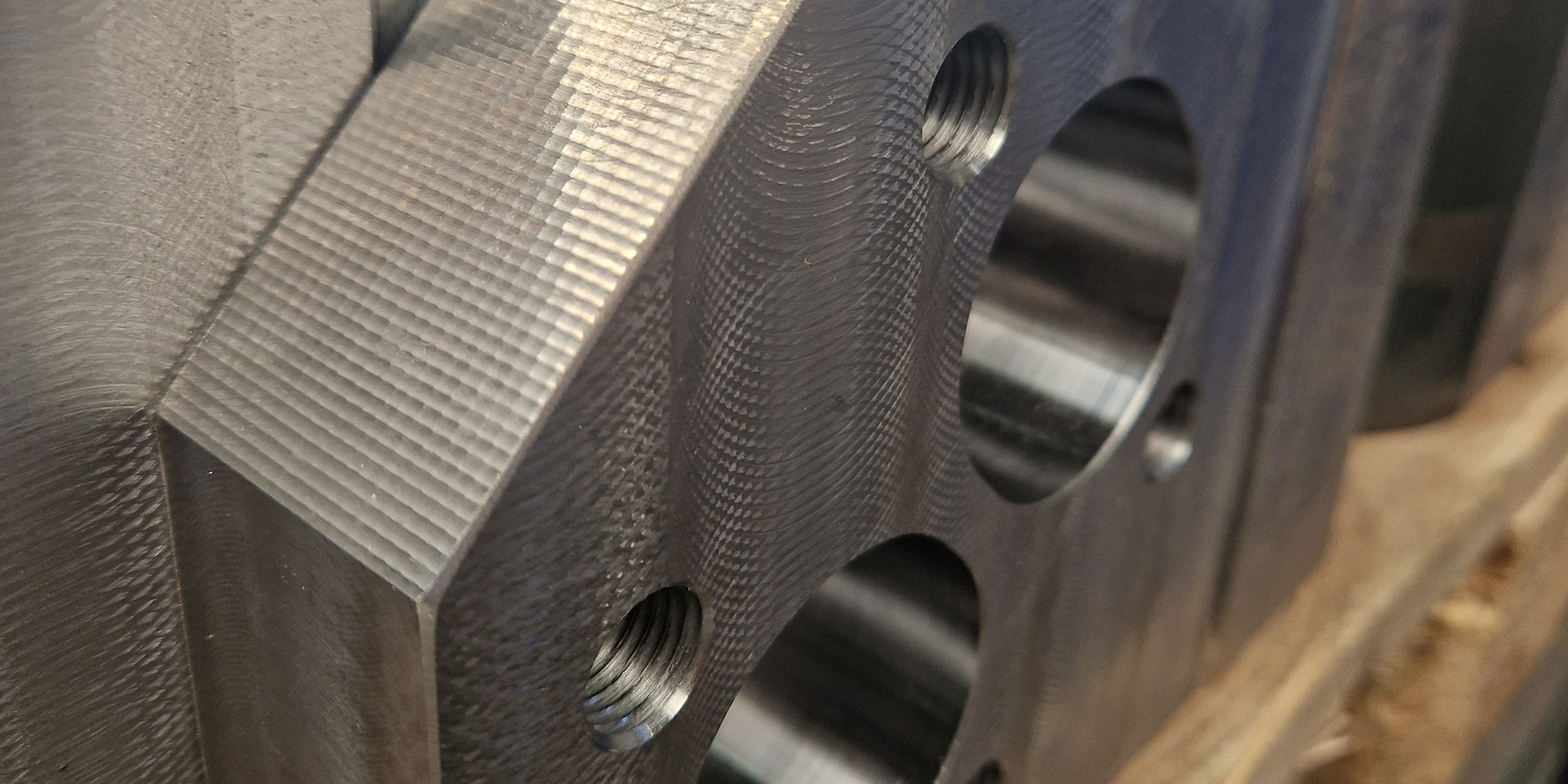

After cutting to size, the components were mechanically milled to ensure exact fitting dimensions. The result is ready-to-install components – directly from the flame-cut to the finished steel component.

Ihre Vorteile – Qualität, Effizienz, SicherheitIn der Zusammenführung aller Schritte liegt der entscheidende Mehrwert: |

|

|---|---|

| Bereich | Vorteile |

| Einkauf | Weniger Lieferanten, einfache Abwicklung, volle Transparenz |

| Produktion | Kein zusätzlicher Bearbeitungsaufwand – direkt verbaubare Teile |

| Logistik | Eine Lieferung, komplette Lösung |

| Qualität | Kontrollierte Prozesse unter einem Dach – keine Toleranzverluste |

| Time-to-Market | Deutlich verkürzte Durchlaufzeit für komplexe Projekte |

S355J2+N is a proven, unalloyed structural steel with good weldability and toughness – ideal for load-bearing structures in mechanical engineering, agricultural technology and industrial plants. The normalized condition (+N) makes it particularly dimensionally stable.

Oxyfuel cutting is suitable for material thicknesses over 50 mm and enables economical cutting with high cutting quality. In combination with mechanical processing, high-precision components are produced – even in small series or one-offs.

The combination of material availability, firing and processing is transferable to many other industries far beyond agricultural engineering:

Wherever thick steel plates are required, UnionStahl supplies the complete solution.

This project shows how UnionStahl understands its role as a partner: We don’t just supply steel – we supply complete solutions. From the bearing plate to the ready-to-install milled part. Fast, precise and with maximum process reliability.

July 2024 is full of exciting developments! We summarize the most important events in our article.

UnionStahl achieves DIN 2303 qualification class 2! Certified expertise for safety-critical welding work on steels and AlZnMg alloys. Discover the highest precision and quality.

The first delivery of the wear-resistant Creusabro® 6400 has arrived! Our wear expert Björn Fischer has personally inspected the delivery and is delighted!