Endurance test for steel: the DWTT test

Resistance to dynamic stress is of crucial importance. The DWTT test focuses on this property and provides important findings.

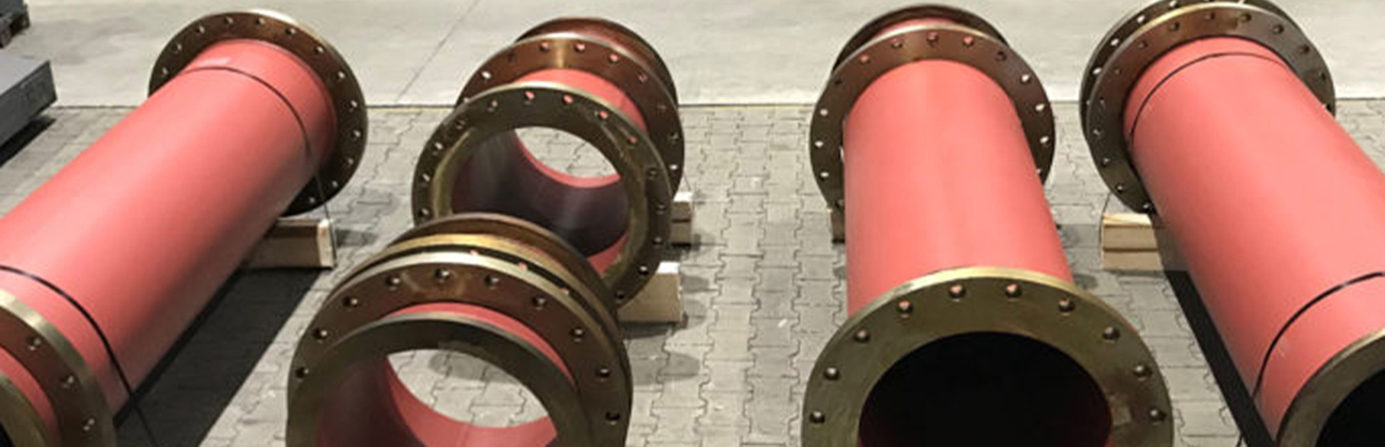

Startseite » News » Creusabro® 4800: Wear-resistant pipes for tunnel driving

Tunnel construction places high demands on the service life and wear resistance of the materials used. With Creusabro® 4800, UnionStahl uses an innovative pre-material for conveyor pipes that is characterized by extremely high durability and thus contributes to increasing efficiency in tunnel construction.

UnionStahl has been working successfully with a world leader in tunnel construction for over 15 years. Until now, this partner has sourced plates and flame-cut blanks in various grades from us, but the development towards ever larger drill heads and pipes in tunnel driving requires new solutions.

With the ever-increasing demands on conveyor pipes, materials must be used that are wear-resistant and durable even under intensive use. The combination of large pipe dimensions and a long service life requires a well thought-out choice of materials in order to minimize downtimes and maximize the efficiency of tunnel driving.

In order to meet the challenges of tunnel construction, we developed a customized solution together with our customer: custom-made pipes made from the highly wear-resistant steel Creusabro® 4800. This material significantly reduces wear and enables the pipes to be used for a long time. The individual production of these pipes involves several work steps, including

Creusabro® 4800 is characterized by a particularly high resistance compared to water-quenched and tempered wear-resistant steels, for example. Compared to conventional wear-resistant steel, Creusabro® materials can be hardened by up to 70 HB under operating conditions. This significantly extends the service life. This property makes Creusabro® 4800 the ideal choice for tunnelling and similar applications where material wear is a major challenge.

Experience with Creusabro® 4800 shows that this material offers optimum conditions for use in tunnel construction. Industeel’s pre-material, which is distributed exclusively by UnionStahl in Germany, Austria, Switzerland, the Benelux countries and Hungary, will also find promising fields of application in other industrial sectors such as mining. For example, its use in diamond mining, especially for suction pipes, is an interesting option for the future.

Resistance to dynamic stress is of crucial importance. The DWTT test focuses on this property and provides important findings.

UnionStahl achieves DIN 2303 qualification class 2! Certified expertise for safety-critical welding work on steels and AlZnMg alloys. Discover the highest precision and quality.

This year’s fall conference was dominated by exciting specialist presentations.

Simply contact us:

Tel: +49 2065 677-0

E-mail: info@unionstahl.com